Silicone Molding Machine

Silicone molding machines are designed to produce high-quality silicone rubber components with precision and consistency. These machines are used in various industries, including automotive, medical, electronics, and consumer goods, to manufacture silicone-based parts. Silicone molding is a highly versatile process that allows for the production of intricate parts with excellent durability and heat resistance.

The silicone molding process typically involves injecting silicone rubber into a mold cavity under controlled pressure and temperature conditions.

Specifications Of Silicone Molding Machine

| Sr. No. | Description | 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

| 1 | Capacity | TON | 60 | 80 | 100 | 150 | 200 | 250 | 300 |

| 2 | Table Size | MM | 300*300 | 350*350 | 400*400 | 500*500 | 600*600 | 750*750 | 900*900 |

| 3 | Daylight Gap | MM | 300 | 300 | 350 | 350 | 350 | 350 | 400 |

| 4 | Cylinder Stock | MM | 250 | 250 | 300 | 300 | 300 | 300 | 350 |

| 5 | Electric Motor | HP | 3 | 3 | 5 | 5 | 7.5 | 7.5 | 10 |

| 6 | Heater Load | KW | 6 | 7 | 7.5 | 9 | 12 | 18 | 24 |

| 7 | Total Load | KW | 9 | 10 | 11 | 13 | 17 | 24 | 32 |

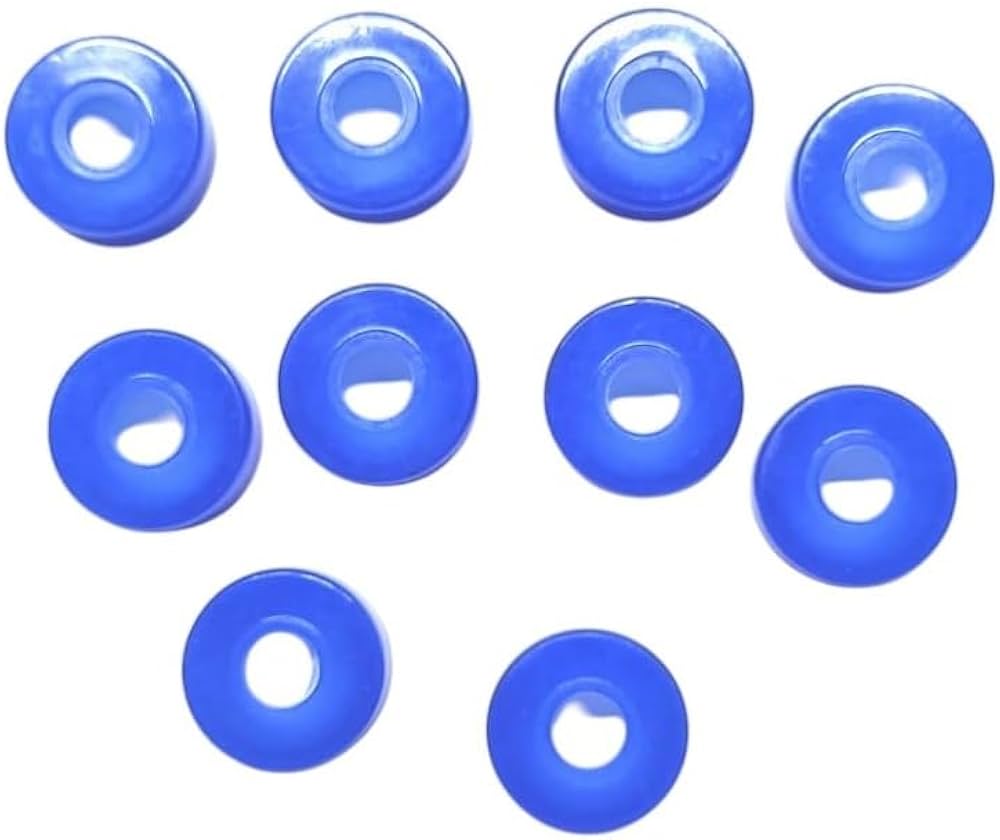

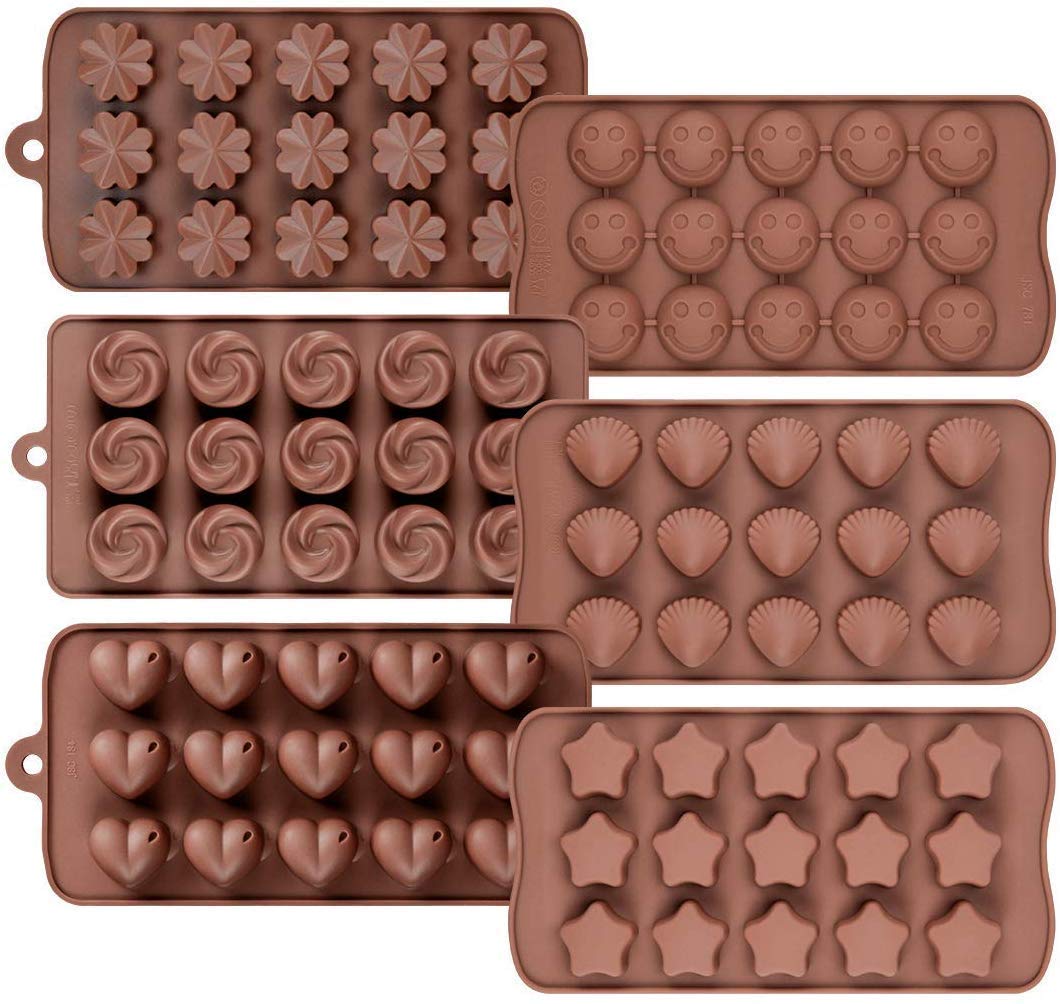

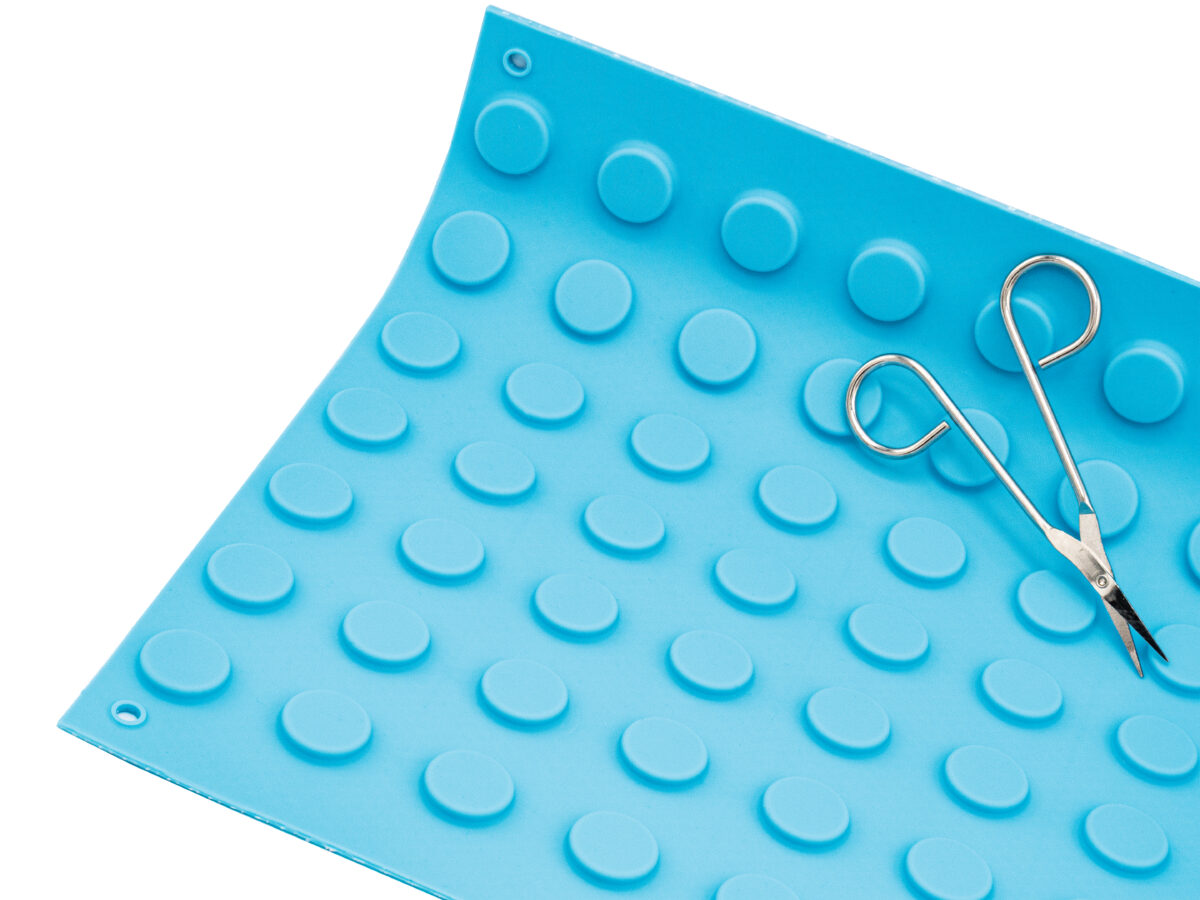

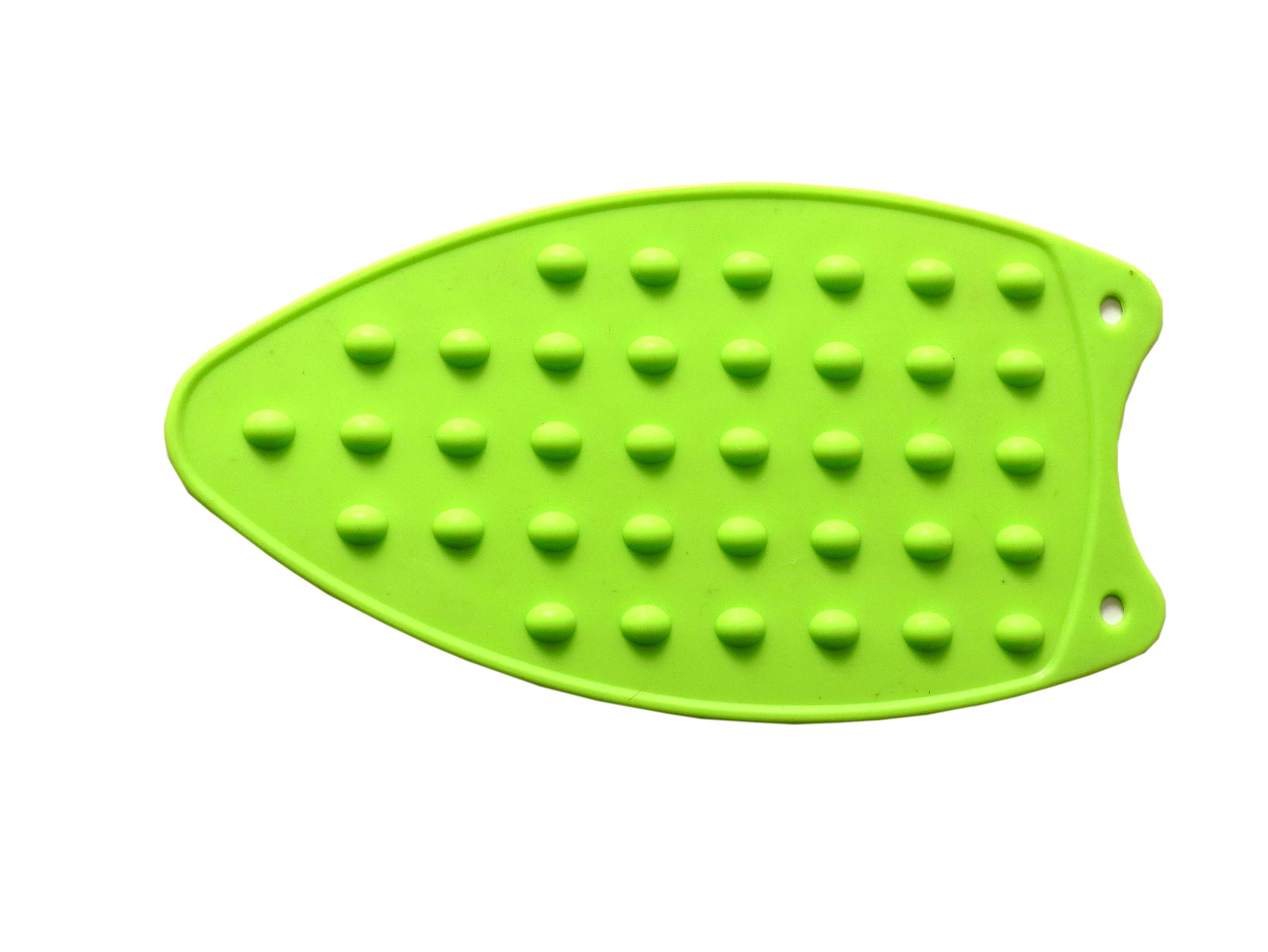

Products Can Be Made

Products Inquiry

Benefits Of Silicone Molding Machine

- High-Quality Products: Silicone molding machines ensure the production of high-quality parts with excellent dimensional accuracy, surface finish, and consistency.

- Enhanced Durability: Parts molded using silicone molding machines exhibit superior durability, heat resistance, and elasticity, making them suitable for demanding applications such as automotive, medical, and industrial products.

- Low Maintenance Costs: These machines are designed for ease of maintenance, with components that are easy to access and replace, which helps reduce downtime and extend the machine's operational lifespan.

- Reduced Cycle Time: Advanced silicone molding machines can reduce cycle times, improving overall production efficiency and helping manufacturers meet tight deadlines and high-volume demands.

Key Points Of Silicone Molding Machine

- Precision in Mold Filling: Silicone molding machines provide precise mold filling, ensuring uniform material distribution and eliminating the risk of air bubbles or inconsistencies in the molded parts.

- Advanced Control Systems: The machines feature sophisticated control systems, allowing operators to fine-tune molding parameters such as temperature, pressure, and curing time for optimal results.

- Energy-Efficient Operation: These machines are designed with energy-saving features, ensuring that silicone components are produced at the lowest possible cost without sacrificing quality.

- Automation Features: Silicone molding machines come with fully automated cycles, reducing the need for manual intervention and ensuring consistent production, especially in high-volume manufacturing environments.

Silicone Molding Machine Video

Applications & Uses Of Silicone Molding Machine

Silicone molding machines are widely used in the medical industry to manufacture components such as seals, gaskets, tubing, and surgical implants. These parts require high precision and biocompatibility, making silicone an ideal material due to its non-toxic and hypoallergenic properties.

Silicone components, such as seals, gaskets, and hoses, are critical in the automotive industry due to their heat resistance, durability, and flexibility. Silicone molding machines are used to produce these parts with high precision and consistency.

Silicone molding machines are used to manufacture parts such as insulating seals, connectors, and keypads for electronic devices. Silicone's ability to withstand high temperatures and electrical insulation properties make it ideal for these applications.

Silicone rubber is commonly used in the production of kitchenware, baby products, and personal care items. Silicone molding machines are used to mold products such as bakeware, spatulas, and silicone mats, ensuring high-quality and durable end products.

In the aerospace sector, silicone molding machines are used to produce components such as gaskets, seals, and thermal insulation parts. These components must be able to withstand extreme temperatures and pressures, and silicone provides the necessary properties.soft-touch buttons. These ensure noise reduction, better grip, and longer product life.

Silicone molding machines are used in various industrial applications, including the manufacturing of seals, O-rings, and custom molded parts that require high durability and resistance to chemicals, heat, and abrasion.